Advancements in Automation for Manufacturing

The manufacturing sector is undergoing a profound transformation driven by continuous advancements in automation. From sophisticated robotics to intelligent software systems, these innovations are reshaping production lines, optimizing operational workflows, and enhancing overall efficiency. This evolution is not merely about replacing manual labor but about creating more adaptive, precise, and high-performing industrial environments capable of meeting the complex demands of a global market. Understanding these developments is crucial for any enterprise aiming to maintain competitiveness and foster sustainable growth in the modern industrial landscape.

Enhancing Production Efficiency and Productivity

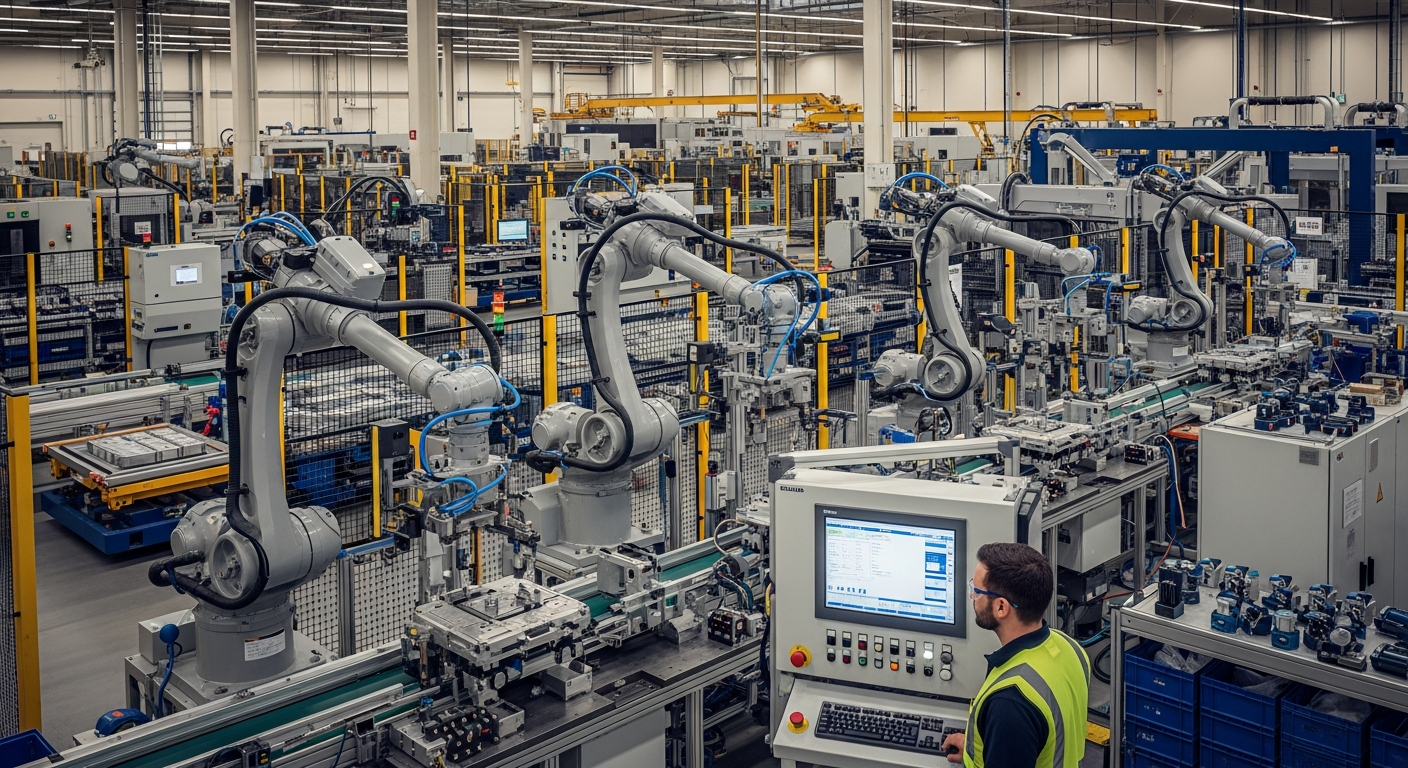

Automation stands as a cornerstone in the pursuit of greater production efficiency and productivity within manufacturing. Modern automated systems, including collaborative robots (cobots) and advanced industrial robots, perform repetitive or hazardous tasks with unparalleled precision and speed. This not only accelerates production cycles but also significantly reduces human error and waste. Integration of these technologies allows for continuous operation, minimizing downtime and maximizing output, which is crucial for meeting high-volume demands in diverse industries. The result is a streamlined manufacturing process that yields higher quality products at a faster rate.

Strategic Integration of Automation in Enterprise Operations

The impact of automation extends beyond the factory floor, fundamentally influencing enterprise operations and strategic planning. Companies are increasingly leveraging automation to integrate various aspects of their business, from design and engineering to inventory management and customer service. This comprehensive approach, often facilitated by enterprise resource planning (ERP) systems and manufacturing execution systems (MES), enables real-time data analysis and informed decision-making. By automating data collection and reporting, management can gain deeper insights into performance metrics, identify bottlenecks, and refine strategic initiatives to optimize resource allocation and foster business growth.

Advancements in Supply Chain and Logistics Automation

Automation plays a pivotal role in revolutionizing the supply chain and logistics sectors, ensuring seamless movement of goods from raw materials to end-users. Innovations such as automated guided vehicles (AGVs), autonomous mobile robots (AMRs), and sophisticated warehouse management systems (WMS) streamline inventory tracking, order fulfillment, and distribution. These technologies enhance accuracy, reduce labor costs, and accelerate delivery times, directly impacting customer satisfaction and market responsiveness. Predictive analytics, powered by automation, further optimizes logistics by forecasting demand and proactively managing inventory levels, thereby minimizing stockouts and overstocking.

Driving Innovation and Market Growth through Technology

Technological advancements in automation are powerful catalysts for innovation and market growth. By automating routine tasks, manufacturers can free up human capital to focus on research, development, and creative problem-solving. This shift fosters an environment where new product designs, improved materials, and more efficient manufacturing processes can emerge. Furthermore, automation enables greater customization and flexibility in production, allowing companies to adapt quickly to changing consumer preferences and market trends. This agility provides a significant competitive advantage, opening new market segments and driving revenue growth for the industry.

Navigating the Future of Manufacturing Processes and Management

The future of manufacturing processes and management will be characterized by even deeper integration of advanced automation technologies. Concepts like Industry 4.0 and smart factories, which involve interconnected systems, artificial intelligence, and the Internet of Things (IoT), are becoming increasingly prevalent. These developments promise further optimization through self-regulating production lines, predictive maintenance, and enhanced human-machine collaboration. Effective management in this evolving landscape will require continuous learning, adaptability, and a strategic focus on workforce development to ensure that human skills complement the capabilities of automated systems, leading to sustainable industrial development and productivity gains.

Automation continues to be a transformative force in manufacturing, driving significant improvements across production, enterprise operations, supply chain management, and overall innovation. Its ongoing evolution promises to reshape industrial landscapes, enabling greater efficiency, adaptability, and growth for businesses worldwide. Embracing these advancements strategically is essential for companies aiming to thrive in an increasingly automated and interconnected global economy.