Impact of Advanced Robotics on Industrial Production

Advanced robotics represents a significant shift in industrial production, reshaping how goods are manufactured and distributed globally. These sophisticated systems are designed to perform complex tasks with precision and consistency, moving beyond traditional automation to integrate artificial intelligence, machine learning, and advanced sensing capabilities. Their influence extends across various sectors, driving changes in operational models, resource allocation, and overall enterprise strategy, contributing to a more dynamic and responsive industrial landscape worldwide.

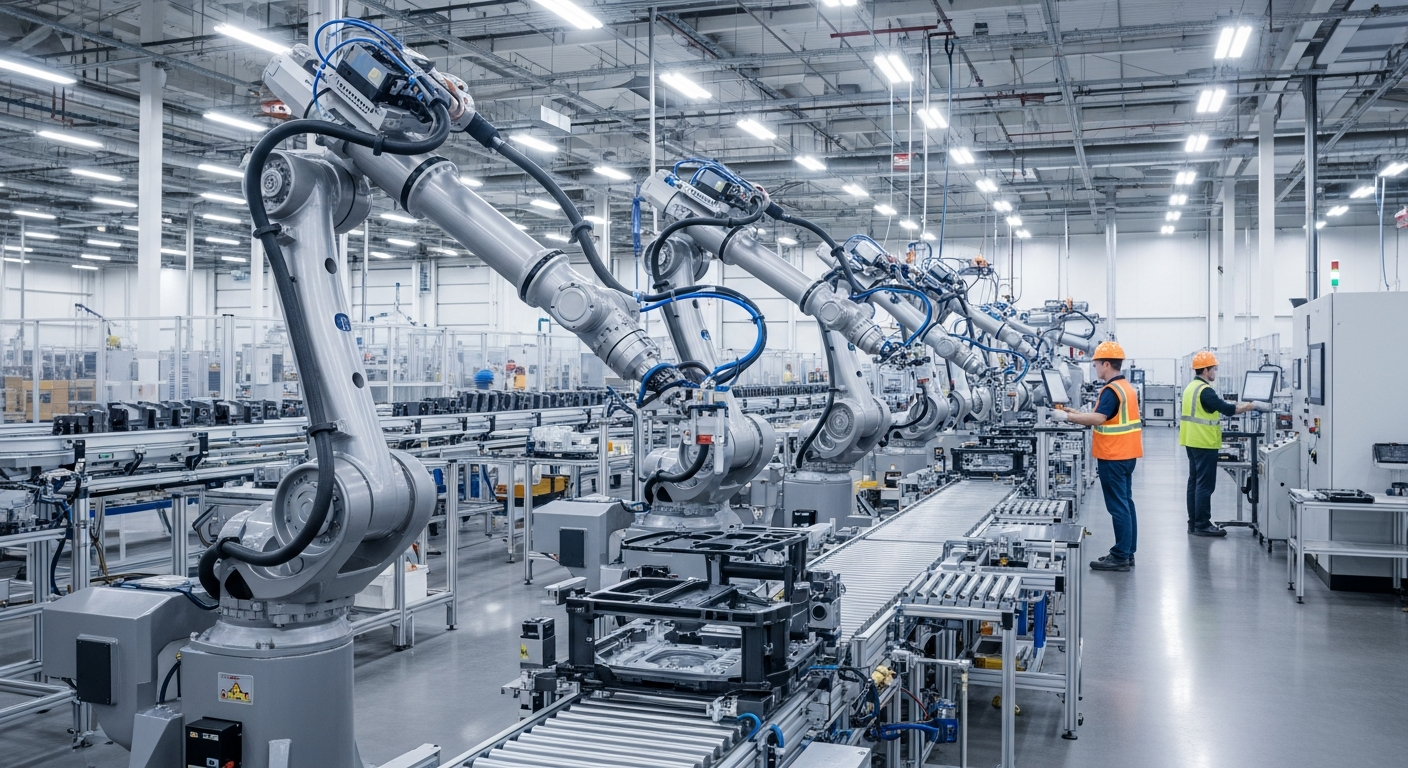

Enhancing Efficiency and Productivity in Production

Advanced robotics plays a pivotal role in boosting operational efficiency and overall productivity across industrial sectors. Robots can perform repetitive tasks with high accuracy and speed, often exceeding human capabilities in terms of consistency and endurance. This leads to reduced cycle times, minimized errors, and a significant increase in output volume. By automating key processes, companies can optimize resource utilization and streamline workflows, resulting in more agile and cost-effective production lines.

Transforming Manufacturing Operations through Automation

The integration of robotics is fundamentally transforming manufacturing operations. Modern industrial robots are not merely fixed machines but adaptable systems capable of handling diverse tasks, from complex assembly to precision welding and material handling. This adaptability allows manufacturers to reconfigure production lines quickly in response to changing market demands or product specifications. The enhanced level of automation contributes to higher quality control, as robotic systems maintain consistent standards throughout the production process, thereby reducing defects and waste.

Innovations in Supply Chain and Logistics

Robotics has introduced substantial innovations within the supply chain and logistics sectors, particularly in warehousing and distribution. Autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) are revolutionizing inventory management, order fulfillment, and material transport within facilities. These systems can navigate complex environments, identify and retrieve items, and transport them efficiently, leading to faster processing times and improved accuracy in order-picking. This level of automation helps optimize storage space and ensures a smoother, more predictable flow of goods from production to delivery.

Strategic Growth and Enterprise Development

The adoption of advanced robotics enables organizations to pursue new avenues for strategic growth and enterprise development. By increasing production capacity and improving product quality, businesses can expand into new markets or meet larger demand volumes more effectively. Robotics facilitates the creation of more resilient and competitive business models, allowing companies to innovate and differentiate their offerings. The ability to scale operations efficiently with robotic assistance supports sustainable development and long-term competitiveness in a globalized economy.

Robotics, Workforce Dynamics, and Management

The introduction of robotics into industrial settings necessitates a re-evaluation of workforce dynamics and management strategies. While some routine tasks may be automated, new roles emerge that require human oversight, programming, maintenance, and collaboration with robotic systems. This shift emphasizes the importance of upskilling and reskilling programs for the existing workforce, fostering a culture of continuous learning. Effective management involves integrating human and robotic teams to leverage the strengths of both, focusing on safety protocols, training, and optimizing collaborative workflows to maximize overall productivity and employee engagement.

Cost Considerations for Industrial Robotics Implementation

Implementing advanced robotics involves significant initial investment, but it can lead to long-term operational savings and improved return on investment. The overall cost is influenced by factors such as the type of robot, its payload capacity, reach, complexity of the application, required software, integration services, and ongoing maintenance. While the upfront expenditure can be substantial, the gains in efficiency, productivity, and quality often justify the investment over time. Organizations typically evaluate the total cost of ownership, including energy consumption, spare parts, and specialized training.

| Robot Type | Typical Application | Cost Estimation (USD) |

|---|---|---|

| Collaborative Robots (Cobots) | Assembly, pick & place, inspection | $25,000 - $50,000 |

| Articulated Robots | Welding, painting, material handling | $50,000 - $150,000 |

| SCARA Robots | Assembly, pick & place, packaging | $15,000 - $40,000 |

| Autonomous Mobile Robots (AMRs) | Material transport, logistics | $30,000 - $100,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Advanced robotics continues to redefine industrial production by offering unparalleled opportunities for efficiency, innovation, and growth. As technology evolves, the integration of these sophisticated systems promises to create more dynamic, responsive, and sustainable industrial environments. Businesses that strategically adopt and adapt to these advancements are better positioned to navigate the complexities of modern markets and secure a competitive edge.